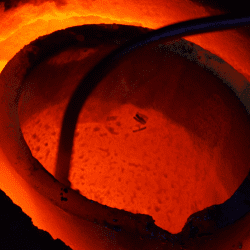

Refining

Precious metals with different purities require different equipment and skills to process. Dillon Gage has the industry experience and tools to be able to handle a variety of metals. And our processing times are the quickest in the industry.

High Grade Refining

We offer industry-leading turnarounds, often within 24 hours, on high grade materials that include:

We offer industry-leading turnarounds, often within 24 hours, on high grade materials that include:

- Karat Scrap

- Silver Scrap

- Sputtering Targets

- Dental Scrap

Low Grade Refining

Our refinery uses maximum efficiency to get the most of low grade material including:

Our refinery uses maximum efficiency to get the most of low grade material including:

- Polishings

- Crucibles

- Slags

- Bench Sweeps

- Manufacturing Residues (Non-Hazardous)